Mechanical Design and Engineering Solutions

Our aviation training applications are now part of Prograde Aerospace

Advancing pilot and instructor development with accurate, repeatable training tools

Mechanical Engineering Services

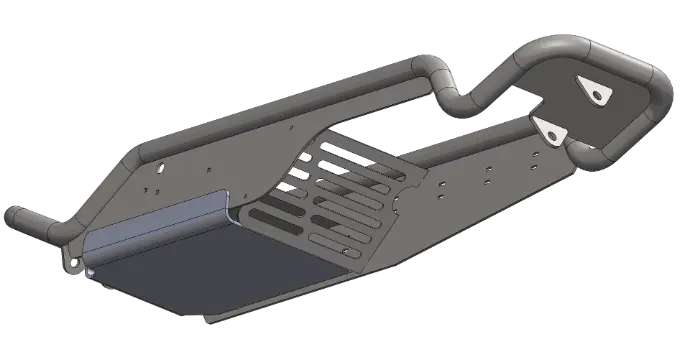

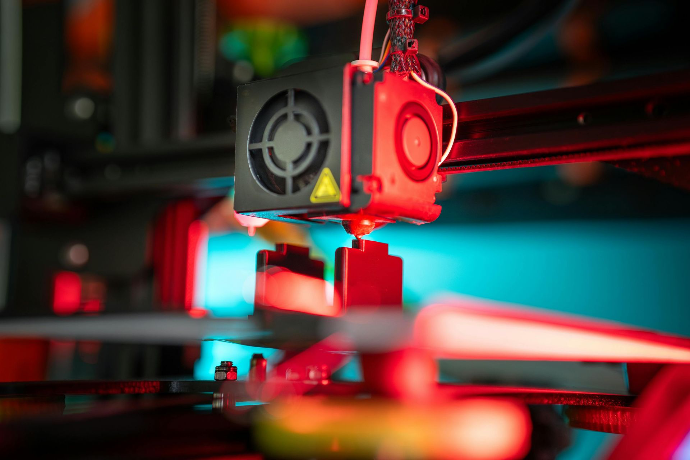

Prograde Engineering provides practical, high-quality mechanical design and analysis solutions for a range of industries. We focus on delivering efficient, compliant, and manufacturable designs that meet real-world demands. With a commitment to precision and engineering excellence, we help clients turn concepts into reliable, functional solutions. See more below.

AVAILABLE FOR NEW PROJECTS Contact usServices

Frequently Asked Questions

Below are some common questions about mechanical design, certification, and analysis services offered by Prograde Engineering across Brisbane, Ipswich, and South East Queensland.

In Queensland, the Professional Engineers Act 2002 requires that any professional engineering service be carried out or directly supervised by a Registered Professional Engineer of Queensland (RPEQ). This applies when engineering judgment or calculations are needed to ensure safety or compliance. Prograde Engineering provides RPEQ-certified mechanical design, verification, and documentation so clients meet their legal obligations under the Board of Professional Engineers Queensland (BPEQ) framework.

An RPEQ engineer in Queensland delivers verified engineering work—drawings, calculations, and certification that demonstrate a design meets safety and compliance standards. At Prograde Engineering, we combine hands-on fabrication understanding with advanced analysis and documentation so your project can proceed confidently to manufacture or site installation.

Yes. Prograde Engineering specialises in concept-to-production mechanical design. We create 3D CAD models, perform calculations, run stress analysis, prepare manufacturing drawings, and support assembly and testing. This process ensures every part is practical to build and compliant with Australian Standards before fabrication begins.

We regularly support OEMs, mining service companies, agricultural equipment manufacturers, and industrial maintenance teams throughout Brisbane, Ipswich, and South East Queensland. Typical projects include bespoke machinery, structural frames, access systems, and prototype components that require certified mechanical design.

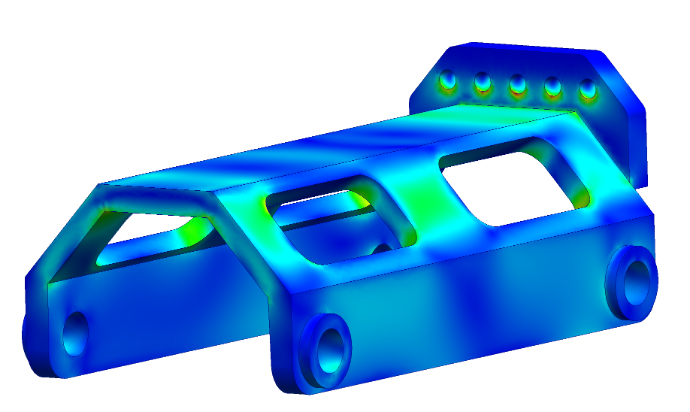

FEA allows us to simulate loads and stresses before anything is built. Correctly applying load cases, boundary conditions, and material properties helps verify that components meet safety factors without over-engineering. Prograde Engineering uses FEA in SolidWorks Simulation to optimise strength, stiffness, and weight while reducing costly redesigns.

Working with a Queensland-based RPEQ mechanical engineer ensures your project meets state compliance requirements and benefits from local manufacturing knowledge. Prograde Engineering is conveniently located in Ipswich and supports clients across South East Queensland, providing responsive service and on-site collaboration when needed.

Ideally, provide photos or sketches, dimensions, intended loads, material preferences, and how the equipment will be used. From there, Prograde Engineering can scope the work, estimate cost, and begin detailed design or verification.

In Queensland, these structures typically follow AS 1657 for access and egress, AS 4100 for structural steel, and AS 3990 for mechanical equipment. Prograde Engineering ensures every design meets those standards, considering live loads, handrail strength, and serviceability limits to keep your site compliant and safe.

Yes. All design work at Prograde Engineering is completed in SolidWorks 3D CAD following AS 1100 drafting standards. Deliverables include detailed drawings with weld symbols, tolerances, material specifications, and parts lists ready for fabrication or machining.

Absolutely. Many projects involve assessing existing machinery or frames that require upgrades or modifications. We review load capacity, fatigue life, and compliance before producing revised drawings and certification, helping clients improve performance without full redesign.

Lifting beams, spreader bars, and access platforms must be shown to comply with AS 4991 and AS 1418 for safe use. Compliance can be demonstrated either by proof-load testing or by independent third-party design verification. Prograde Engineering can perform the third-party assessment, reviewing load paths, stress concentrations, and safety factors to confirm the design meets Australian Standards and site requirements.

Yes. Prograde Engineering designs and verifies custom lifting devices, such as spreader beams, lifting frames, and jigs, in accordance with AS 4991 Lifting Devices. We handle everything from concept and FEA through to RPEQ third-party certification or proof-load coordination. This service helps Queensland manufacturers and site teams obtain compliant, practical lifting solutions ready for safe use.

Yes. We assist OEMs and small manufacturers in setting up drawing templates, revision control, file naming systems, and configuration management aligned with ISO 9001 principles. Establishing these systems increases design consistency and reduces errors during manufacture or service.

© 2025 Prograde Engineering. All rights reserved.